Hydraulic cylinders are also known as hydraulic rams and they convert fluid energy into linear force. Hydraulic cylinders get their power from pressurised hydraulic fluid, which when pressurised, acts on the piston of the cylinder. This force causes the piston to move in a linear motion.

One of the necessary hydraulic components of any hydraulic system is the actuator. Actuators allow hydraulic systems to realise the required action of mechanical power. Hydraulic actuators can create torque (twisting force) or linear (straight line) force - linear force actuators can be hydraulic cylinders.

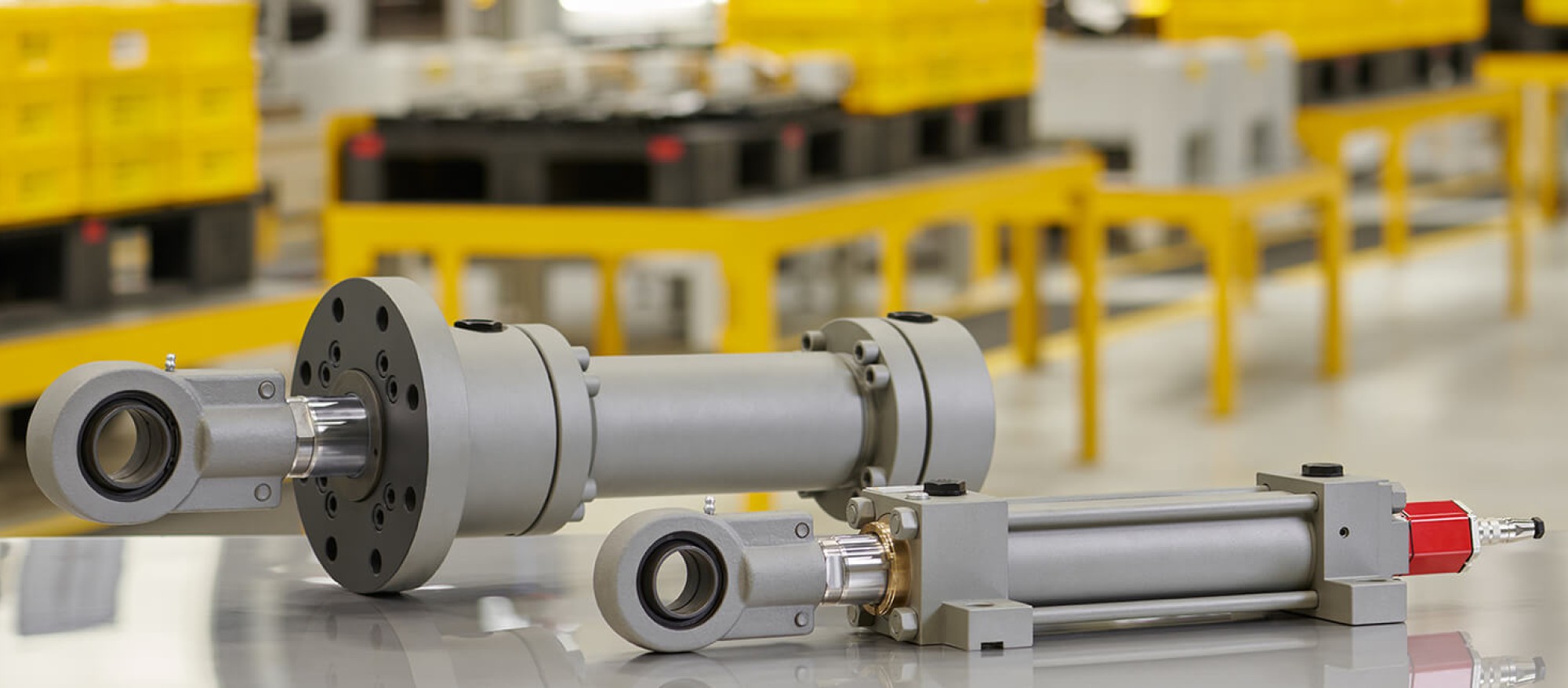

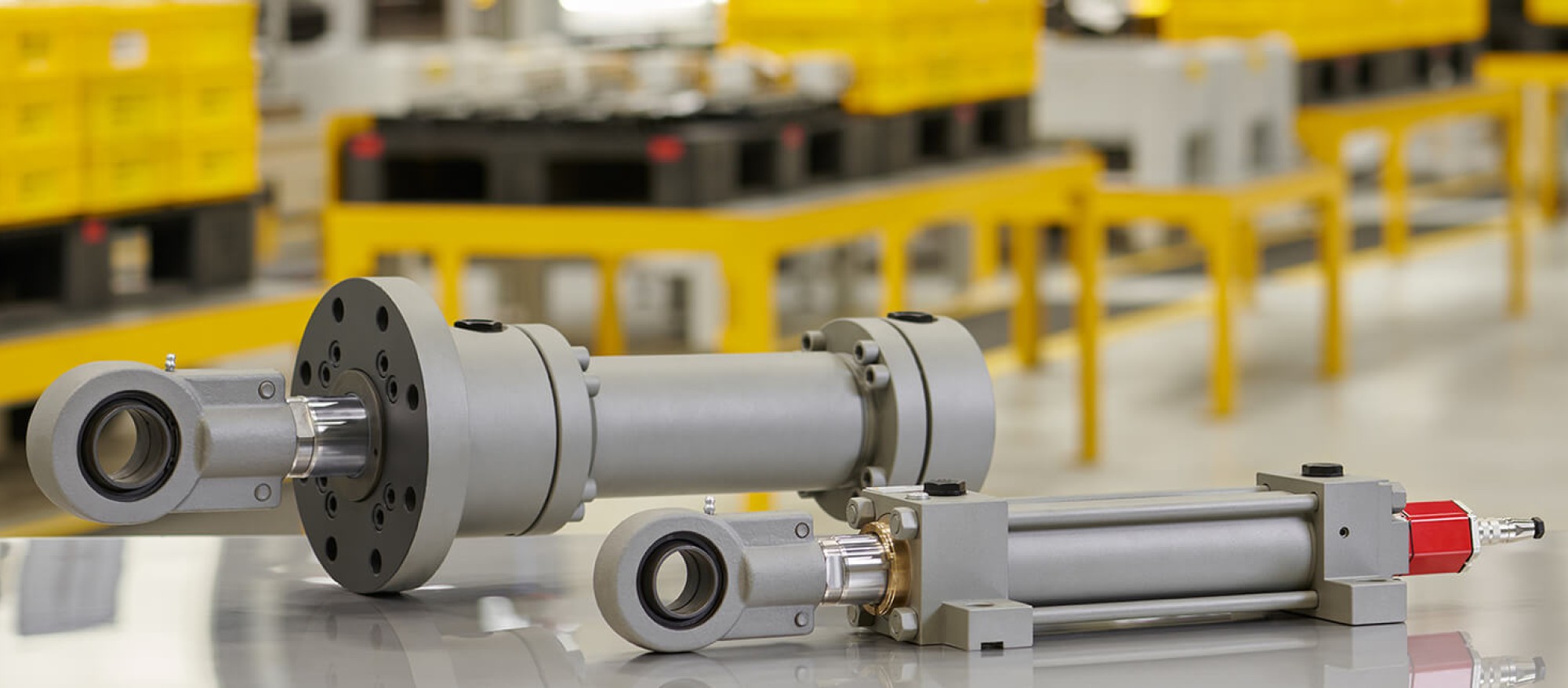

Tie-rod, welded and mill type hydraulic cylinders are essentially the three styles of hydraulic cylinder construction used today. In operation, hydraulic cylinders are usually double-acting, or single-acting.

It is possible to create a hydraulic system that can pull, push and lift different loads by using different sized hydraulic cylinders. Flexibility in design and structure when transferring force is achieved with hydraulic cylinders.

Ports at both the bore and annulus ends for pumping fluids give the name of these cylinders - double acting. The ports at either end of the cylinder provide access for the flow of hydraulic fluid and movement in both directions. Double acting hydraulic cylinders are usually found in most rising and lowering devices, such as presses.

The piston rod extends when fluid is pumped into the bore end, and only in a single direction. An external force aided by gravity is required to return operation and convert to a non-pressurised state where the hydraulic fluid returns to the reservoir. Single acting hydraulic cylinders can be seen in hydraulic jacks.

Telescopic hydraulic cylinders can be either single or double acting. They contain nested tubings, called stages, with the diameter of each nested tube becoming smaller as the cylinder extends.

High-strength threaded steel rods hold the two end caps to the cylinder barrel in tie rod hydraulic cylinders. Small bore cylinders usually have 4 tie rods, while large bore cylinders requiring as many as 16 or 20. in order to retain the end caps under the tremendous forces produced. Tie rod cylinder applications are mostly industrial and manufacturing and advantages include ease of maintenance, repair, and assembly.

These hydraulic cylinders have no tie rods but the end caps are welded to the barrel. The benefit of welded hydraulic cylinders is their compact construction, internal bearing lengths and duty cycle. Common application of these cylinders is in mobile hydraulic applications.

The end plug and cap in mill type hydraulic cylinders are bolted to flanges that are generally welded to both ends of the main tube. The flanges include an array of holes and both the end plug and cap are offered to a flange on either end of the tube, high strength bolts are then fitted and torqued to a specific value to hold the end cap and plug in place.

As is common in many hydraulic processes the operation of hydraulic cylinders is based on Pascal‘s Law in fluid mechanics. The pressure is equal to the force divided by the area on which it acts.

The pressure is the applied force over a surface as; P=F/A >>F is the used force and A is the surface area. So, pressure applied on a piston produces an equal increase in force.

Hydraulic cylinders can only be used in linear force applications for pushing and pulling. Bending or side loads should never be transmitted to the piston rod or cylinder.

Hydraulic cylinders consist of a number of hydraulic components all working together to create linear force. A steel cylinder barrel is connected to a completely smooth piston rod that is able to move back and forth with very limited friction. The cylinder barrel is closed on each end by the cylinder bottom (also known as the “cap end”) and by the cylinder head, where the piston rod comes out of the cylinder.

The hydraulic cylinder barrel has to be sealed at both ends to avoid leaking. The base, or cap end, is sealed, but the “rod end” is sealed with a neck gland to allow the piston to move in and out. There are multiple and various seals used through a hydraulic cylinder‘s construction and these seals will be determined during the process of designing the hydraulic system.

Posted by admin in category Hydraulic Motors Advice on Friday, 21st January 2022

Call our knowledgeable team Mon–Fri 8:30am–5pm

Systems & Components Division 01427 874445

sales@hydrastore.co.uk

Hose Division 0121 326 6395

hoses@hydrastore.co.uk

Hydrastore use cookies to make the site run smoothly, enhance the content and to gather information on how you use it in order to improve and personalise your experience. See our Privacy Policy