A hydraulic system is the powerhouse behind countless machines we use in our daily lives, from car brakes to construction equipment. But what makes these systems so powerful? It’s all in the components. Understanding hydraulic system components is key to designing efficient, high-performing machinery, whether for industrial applications or mobile hydraulic systems.

Here, we’ll break down each essential component, its function, and how it works together to create the hydraulic power that drives much of today’s machinery.

A hydraulic system is designed to transfer energy through an incompressible fluid, typically hydraulic oil or specialised hydraulic fluids. By forcing this fluid through various components, a hydraulic system can convert mechanical energy into hydraulic force and then back again, allowing for significant mechanical power to be applied where needed.

These systems rely on precise control of fluid flow and pressure to operate efficiently. Each component must work seamlessly together to avoid system failure.

The hydraulic fluid is the lifeblood of the entire system. It transfers energy, lubricates, and cools the system’s components. The type of hydraulic fluid used can vary depending on the type of hydraulic system. Still, standard options include mineral-based oils, synthetic fluids, and even biodegradable options for environmentally conscious applications.

Key properties of hydraulic fluid:

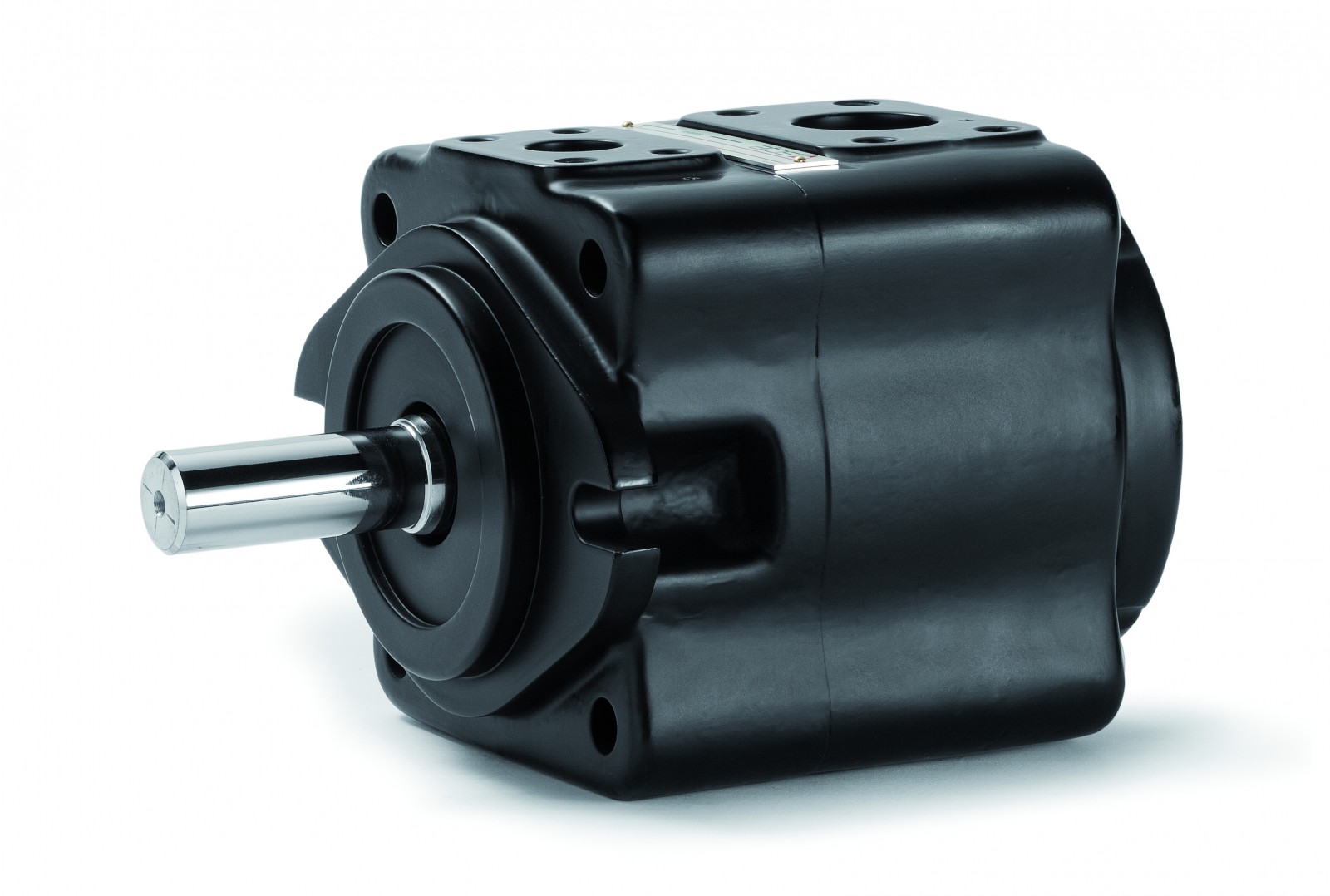

The hydraulic pump is responsible for converting mechanical energy into hydraulic energy by moving the hydraulic fluid throughout the system. Pumps come in different forms, each suited to specific applications:

The type of pump you choose directly affects system pressure and flow rate, vital for achieving the desired performance.

The hydraulic fluid reservoir is where the system stores and maintains the hydraulic fluid. This component also allows air bubbles to escape, ensuring smooth operation by keeping the fluid uncontaminated. The reservoir plays a significant role in system health by:

Hydraulic valves regulate the flow and direction of hydraulic fluid, playing an essential role in system control. Several types of valves are typically involved:

You can ensure optimal system performance and avoid costly downtime by carefully selecting and maintaining valves.

Actuators convert the hydraulic energy back into mechanical energy. They come in two main types:

These components convert hydraulic energy into the motion and force required by specific applications.

Hydraulic hoses and fittings connect different hydraulic system parts, ensuring fluid flow between components. The quality of these hoses impacts:

A filter is a critical component that keeps contaminants out of the hydraulic fluid, which is key for system efficiency and longevity. There are several types of filters, including inline and return filters, each can be positioned to catch debris before it causes damage.

Filters are essential for maintaining optimal fluid performance, particularly in heavy-duty applications where fluid contamination and oil degradation can lead to expensive breakdowns.

When a hydraulic system is operational, each component works in unison to achieve the desired output:

This cycle continues, with each part ensuring that system pressure, flow rate, and mechanical energy are balanced for the task at hand.

Selecting the right components for a hydraulic system can make all the difference in system efficiency and longevity. Consider these factors:

Different hydraulic systems require different setups. For example:

Choose a hydraulic fluid compatible with the other system components to prevent premature wear and corrosion. Some applications require specific fluid types, such as biodegradable options for environmentally sensitive areas.

Selecting components that can handle the required system pressure is essential. Pumps, hoses, and actuators must be rated for the specific pressures your application demands.

By carefully choosing components like pressure control valves, flow control valves, and high-quality hoses, you can optimise system performance for energy efficiency, resulting in significant cost savings over time.

Regular maintenance is critical to keeping a hydraulic system running smoothly. To reduce downtime and extend component life, consider built-in filters, accessible reservoirs, and durable fittings.

Maintaining a hydraulic system involves routine checks on each component to ensure efficient operation and prevent system breakdowns. Key maintenance tasks include:

Investing in high-quality hydraulic components is essential for any operation that depends on hydraulics. Quality parts mean:

When you know the fundamental components and their roles in a hydraulic system, you can make informed decisions that lead to optimal system performance and longevity.

Every hydraulic system is a unique combination of components, each serving a specific function to ensure smooth, powerful operation. Understanding these components helps ensure the efficiency and reliability of any hydraulic system. Whether you're dealing with a small mobile unit or a large industrial setup, the right combination of pumps, reservoirs, valves, actuators, and hoses will make all the difference.

Posted by admin in category Hydraulic Systems Advice on Friday, 25th April 2025

Call our knowledgeable team Mon–Fri 8:30am–5pm

Systems & Components Division 01427 874445

sales@hydrastore.co.uk

Hose Division 0121 326 6395

hoses@hydrastore.co.uk

Hydrastore use cookies to make the site run smoothly, enhance the content and to gather information on how you use it in order to improve and personalise your experience. See our Privacy Policy