Hydraulic systems use pressurised fluid to give power that moves machines with ease and force. hydraulics offer consistent torque and power through fluid transmission, providing a reliable solution for tasks requiring substantial force and precision.

So, how does hydraulics work in a hydraulic system? First, fluid enters connected components like pumps, valves, and actuators. The pressure and flow of this fluid are monitored and kept stable, which optimises system performance. This pressurised fluid flows through hoses and pipes to power hydraulic cylinders, motors, and other hydraulic actuators.

Hydraulic systems work using Pascal's Law, a simple rule that states that when pressure is applied to a confined fluid, it is transmitted undiminished in all directions. This idea allows these systems to transmit a lot of power without losing strength, even when pressure is very high.

A hydraulic system relies on various essential elements that work together to control fluid pressure and movement. These components play distinct roles and are designed to handle specific system requirements:

Hydraulic systems function by pressurising fluid within a network of components to achieve specific motion or force. When fluid enters the pump inlet, the pump provides flow and pressure to the system. Flow and pressure are carefully controlled to meet the system's requirements.

Controlling fluid flow is crucial for maintaining consistent system performance. Flow control valves are one way to regulate the speed of fluid transmission. In contrast, pressure relief valves prevent excess pressure buildup, which could damage components or compromise safety. Properly balanced flow rate and pressure allow the system to operate efficiently, even under varying load conditions.

Hydraulic systems offer benefits over electric or pneumatic systems. But why do they often fit heavy equipment and industrial applications so well?

Hydraulic and pneumatic systems use either air or fluid power to create force. Here are the main differences:

Engineers must consider several system requirements when designing hydraulic systems to ensure optimal performance and system longevity. Here are some essential steps:

Choosing the correct hydraulic fluid is crucial. Viscosity and fluid selection directly impact flow rate, heat dissipation, and efficiency. The fluid’s viscosity should match the operating temperature range to prevent wear on components and ensure heat dissipation within the system.

Determining the pressure and flow requirements for the application is critical. High pressure is ideal for systems that require substantial power, while lower pressure may be sufficient for lighter tasks. Ensuring the correct flow velocity helps to avoid issues like leakage and pressure loss, which can affect system performance.

A well-designed hydraulic circuit maximises efficiency and effectively controls fluid flow. To manage fluid pressure and prevent overheating, the circuit should include pressure relief valves, flow control valves, and bypass valves.

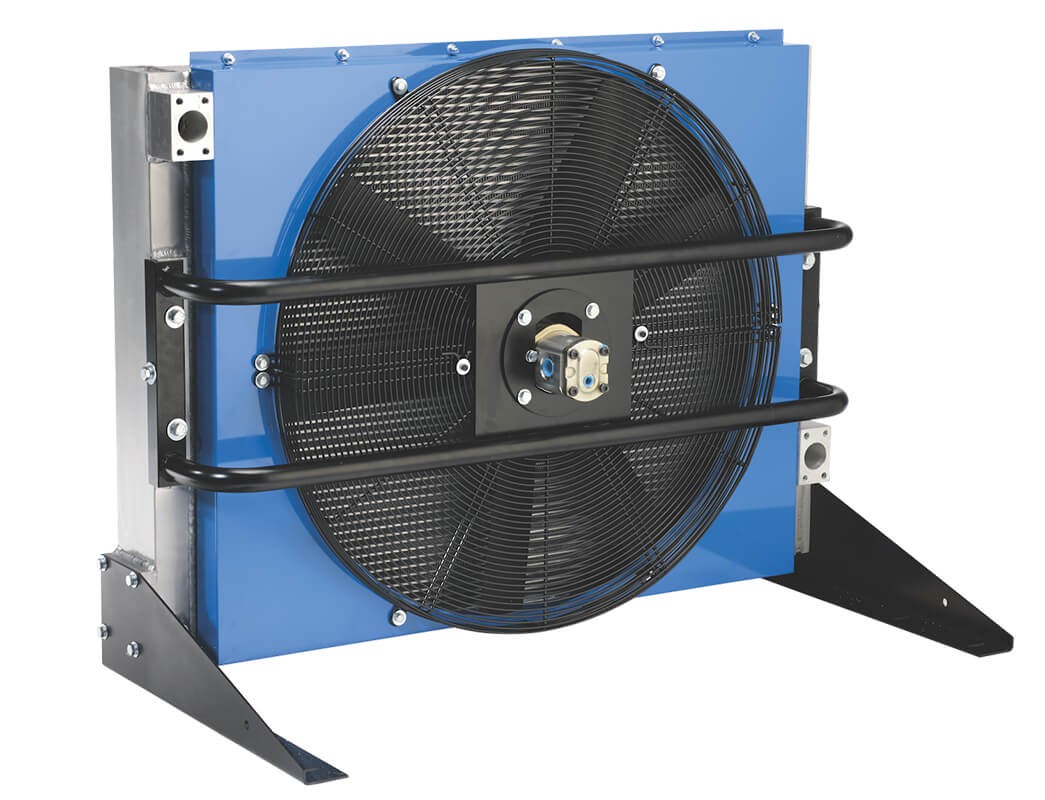

Good heat management keeps the system running at its optimal temperature range. Heat exchangers reduce extra heat, and the correct reservoir design helps with cooling and stops fluid degradation.

To enhance system efficiency, consider these best practices:

Optimised Circuit Design: Design hydraulic circuits to reduce energy loss caused by high pressure drops, reduce hose runs and consider efficient routing to improve both flow and pressure transfer.

Posted by admin in category Hydraulic Systems Advice on Friday, 25th April 2025

Call our knowledgeable team Mon–Fri 8:30am–5pm

Systems & Components Division 01427 874445

sales@hydrastore.co.uk

Hose Division 0121 326 6395

hoses@hydrastore.co.uk

Hydrastore use cookies to make the site run smoothly, enhance the content and to gather information on how you use it in order to improve and personalise your experience. See our Privacy Policy