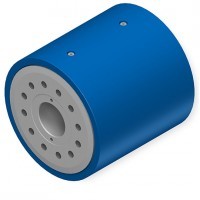

At Hydrastore, we have a wide stock of top-quality and durable rotary actuators. These hardworking components provide an angular or rotating movement, whilst providing very high torque and accurate positioning. Some applications require both lift and turn functionality in a compact package, HKS actuators provide such equipment.

If you‘re looking for a rotate and lift actuator, for a heavy-duty lifting application such as a rubbish truck, we have a selection from leading engineering brand, HKS Partners. The German manufacturer specialises in robust and reliable rotary actuators, which are used across the globe, including in deep-sea environments.

Their powerful rotate and lift rotary actuators are found worldwide in production lines, in mines and in manufacturing industries - anywhere where loads need to be both lifted and turned.

Hydraulic rotary actuators play a crucial role in industries that require powerful, reliable motion control. By converting hydraulic pressure into rotational motion, these devices are essential in manufacturing, automation, and heavy machinery.

A hydraulic rotary actuator convert hydraulic fluid pressure into controlled rotational motion. Whereas linear actuators move in a straight line, rotary actuators create rotational motion that can range from a few degrees up to full 360° turns. This makes them ideal for applications that require precise and powerful torque in compact spaces.

Key components include a cylinder, piston, and output shaft, which work together to produce the desired angle of rotation.

There are several types of hydraulic rotary actuators, each suited to specific applications.

A rotary vane actuator has a rotor fitted inside a cylinder. The vane, which is fixed to the rotor, divides the cylinder into chambers. Hydraulic fluid is pumped into a chamber causing the vane to rotate. Rotary vane actuators are compact and capable of continuous rotation. They're often used for applications requiring smooth, low-speed motion such as in automation and industrial settings.

The rack and pinion setup delivers a high torque output. Hydraulic pressure pushes a piston attached to a rack, which then drives the pinion gear. The motion produced by the mechanical efficiency of the rack and pinion setup means powerful, adjustable output torque in a wide range of rotation angles.

By using a helical spline mechanism these actuators convert linear motion into rotation. Pressurised fluid moves the piston, which then turns the output shaft. This type of actuator offers continuous rotation and high torque for applications requiring precise control over angular movement. They're ideal for heavy-duty applications.

Hydraulic, pneumatic, and electric rotary actuators, each have unique characteristics and preferrable applications:

Hydraulic rotary actuators stand out for their ability to deliver high torque, making them suitable for applications requiring significant force and control. They also have a high mechanical efficiency and can operate under extreme conditions, which is crucial in industries like aerospace and construction.

Hydraulic rotary actuators are widely used in industrial applications. The below are some common uses, but we can see these actuators in use across many more applications.

In manufacturing, these actuators can automate a variety of tasks, from rotating components to adjusting machinery. They are commonly used to rotate clamps, fitting tools, or even transfer parts on assembly lines. Their compact design means they can also be used in tight spaces, making them versatile for robotic automation.

In the aerospace sector, hydraulic rotary actuators are used in applications like controlling flaps, landing gear, and brake systems. Their ability to handle differential pressure and work under extreme conditions makes them perfect for high-stress environments.

These actuators are integral to earth-moving equipment, cranes, and other heavy-duty machinery. They help control the pivoting and rotating mechanisms, as well as control arm movements. The high torque output is essential for moving heavy loads or adjusting the positioning of large components.

Marine environments demand equipment that can handle corrosion, moisture, and heavy loads. Hydraulic rotary actuators are found in winches, cranes, and rudder controls on ships, as well as offshore drilling rigs, where they withstand harsh conditions while delivering powerful and precise control.

It's best to understand a few factors before selecting the right hydraulic rotary actuator:

Ensure mechanical efficiency and prevent issues through regular maintenance. Here are some practical tips:

With advances in automatic systems and robotics, hydraulic rotary actuators are becoming more sophisticated. Integration with IoT systems for real-time monitoring, smart sensors for position control, and developments in seal technology are enhancing actuator reliability and efficiency. Newer compact designs are also making these actuators suitable for smaller machines.

For industries relying on powerful motion control solutions, hydraulic rotary actuators are still a must-have. Their adaptability, combined with high output torque and reliability, makes them the go-to choice in industrial and heavy-duty applications.

German-based engineering firm HKS Partners has been designing and making industry-leading engineering components since 1970. Renowned for their top-quality products, they are one of our most trusted suppliers. At Hydrastore, we‘re confident to recommend HKS actuators, as they‘re built to last and to an extremely high specification.

Working worldwide, HKS makes rotatory actuators for a whole range of specialist applications, from bin truck rotate and lift components to super-tough shipbuilding and industrial equipment. Everything is built to work in robust and challenging environments and with the brand‘s signature precision.

At Hydrastore, we have a comprehensive selection of rotate and lift actuators from HKS Partners. We also stock their mobile, offshore and industry series ranges of rotary actuators.

If you would like to know more about any of these rotary actuators, please contact us at Hydrastore. We‘ll talk to you, engineer to engineer, and make sure you have the right component for the job.

A hydraulic rotary actuator converts hydraulic energy into precise rotational motion. It's crucial for systems needing power and precision, such as industrial machinery and aerospace technologies.

They operate using mechanisms like vane, piston, or rack and pinion systems. Vane actuators use differential pressure; piston-based actuators use hydraulic fluid, and rack and pinion systems convert linear motion into rotational motion.

The main types include single-acting and double-acting actuators. Single-acting actuators move in one direction, often with a return spring, while double-acting actuators offer bidirectional control.

Vane-type actuators use differential hydraulic pressure to create rotational motion. They are compact, efficient, and suitable for applications requiring precise control.

Consider factors like torque, angle of rotation, load capacities, and operating environment. For heavier loads, piston-type actuators are ideal; for lighter loads, rotary vane or rack and pinion actuators suffice.

They are used in heavy machinery for operations like fitting and clamping, in aerospace for controlling surfaces and landing gear, and in robotics for precise articulated arm movements.

Rotary actuators offer limited, precise rotational motion, while hydraulic motors provide continuous rotation and higher torque output. Rotary actuators are more compact and suited for tasks needing fine control.

HKS rotary actuators, available at Hydrastore, are known for their reliability and performance. They are used in various applications, including industrial systems and renewable energy setups like solar panel trackers.

Hydrastore use cookies to make the site run smoothly, enhance the content and to gather information on how you use it in order to improve and personalise your experience. See our Privacy Policy