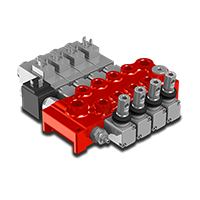

Monoblock valves are generally less expensive than sectional valves, as well as being lighter and more compact. With no sectional leak points, installation of Hydrocontrol monoblock valves removes potential fitting issues.

Hydrocontrol boasts one of the most complete mobile control valve ranges of any manufacturer in the world and has a well-earned reputation for high-quality, innovative and cost-effective products.

Hydrocontrol offers a large range of monoblock directional control valves. These products, manufactured to the highest quality standards, are very flexible and can be adapted to a multitude of applications. A selection of these monoblock valves are available for next day delivery from the Hydrastore web shop.

Mobile hydraulic applications for Hydrocontrol monoblock valves include agricultural machinery, mobile cranes, mini dumpers, forklift trucks, as well as various kinds of excavators and loaders.

A monoblock valve is a type of directional control valve housed in a single, solid block. These valves manage the flow of hydraulic fluid to different parts of a system, enabling various functions in machinery and equipment. By controlling the direction of fluid flow, monoblock valves play a vital role in ensuring the correct operation of hydraulic circuits.

The monoblock construction offers leak-proof performance, which is essential in heavy-duty applications where working pressure can exceed 250 bar. Their robust design makes them suitable for both mobile and industrial equipment, offering single and double-acting functions with various spool configurations.

Monoblock valves are known for their simplicity and durability, but here’s a breakdown of what makes them popular:

These valves are often a popular choice for hydraulic applications due to their space-saving and cost-effective design.

These are the most commonly used directional control valves, suitable for straightforward applications. Standard monoblock valves come with options for different spool positions and configurations, such as 2-way, 3-way, or 4-way. You’ll also find versions that support both single and double-acting cylinders.

These detented valves stay in a particular position without needing constant input, ideal for applications where you need to keep the flow moving in one direction without holding a lever. They’re commonly used in mobile equipment like tractors, where continuous flow is necessary.

For systems that require specific flow rates, pressures, or spool types, special monoblock valves are available on request. Manufacturers can often provide custom solutions tailored to unique hydraulic circuit needs.

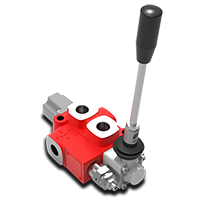

In a hydraulic circuit, monoblock valves regulate the direction and rate of flow. They contain a spool, which is connected to a lever. Moving the lever shifts the spool, allowing hydraulic fluid to move through designated ports. The spool’s position determines the direction in which the fluid flows, controlling the operation of single or double-acting cylinders.

Most monoblock directional control valves are fitted with a spring-return mechanism, ensuring that the spool returns to the neutral position after the lever is released. For continuous flow, detented spools hold the spool in place, keeping the valve in an open position without needing to hold the lever down.

Monoblock valves are versatile and used in a range of industries and applications. Here are some typical uses:

When selecting a monoblock valve for your application, consider the following factors:

If you’re unsure which monoblock valve type is best for your equipment, many suppliers offer consultation services to help you make the right choice.

Proper operation and maintenance extend the lifespan of monoblock valves and ensure they function at peak efficiency. Here are some essential maintenance tips:

Regular maintenance can keep your monoblock valves functioning smoothly, reducing downtime and preventing expensive repairs.

Depending on your needs, monoblock valves come in different configurations to suit specific applications:

Advancements in hydraulic technology have improved the efficiency and durability of monoblock valves. Many manufacturers now offer models with advanced sealing technology, leak-proof designs, and optimised spools for enhanced fluid control. For those in need of specialised valves, custom models are available, tailored to specific pressure and flow requirements.

To find the latest monoblock valves, you can browse catalogues from well-known brands or reach out directly for specific product codes and availability. Many suppliers provide detailed specifications for each model, allowing you to choose based on precise application needs.

In summary, monoblock valves are a vital component in many hydraulic systems, providing robust, efficient, and cost-effective flow control. With various configurations available, they offer the flexibility needed for everything from agricultural machinery to industrial equipment. By understanding the features, applications, and options for customisation, you can select the right monoblock valve to optimise your hydraulic operations.

Hydrastore has considerable expertise gained from many years of experience in the design and manufacture of mobile hydraulic systems. Get in touch with one of our experts now to discuss your hydraulic system requirements.

Hydrastore use cookies to make the site run smoothly, enhance the content and to gather information on how you use it in order to improve and personalise your experience. See our Privacy Policy