Hydraulic systems exist everywhere, like car brakes and big industrial machines. They change mechanical energy into hydraulic energy using pumps, valves and cylinders. How does this all happen? We will simplify hydraulic system operation and learn about the parts that allow these systems to generate substantial power.

How Does a Hydraulic System Work?

A hydraulic system takes fluid under pressure to make mechanical energy. We've simplified the process for you so you get an overview of how these systems work:

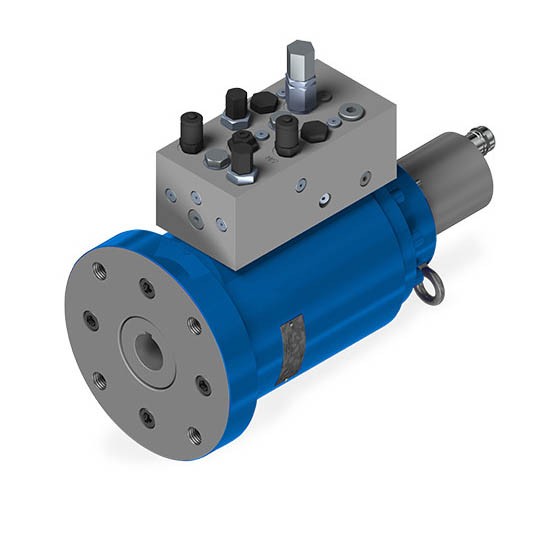

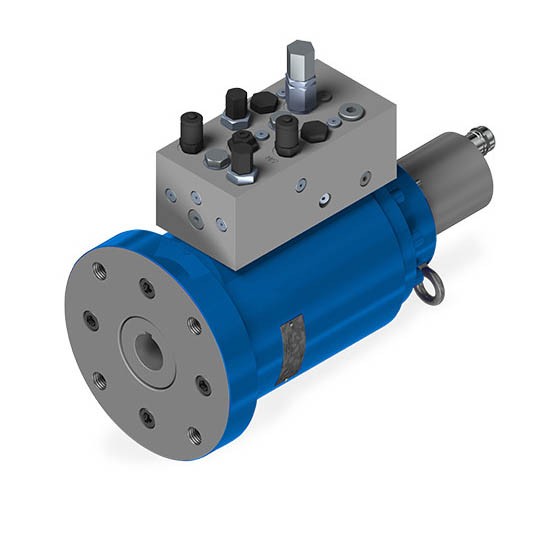

- Hydraulic Pump: These start the process by transforming mechanical energy into hydraulic energy. The pump pushes hydraulic fluid through the system, which creates flow and can provide pressure. There are a few options when it comes to pumps, such as piston pumps and variable displacement pumps - take a look at our hydraulics pumps page for more information.

- Hydraulic Fluid: The means by which a system transfers energy. Hydraulic fluid is typically an oil-based liquid that can be pressurised and as it moves through hoses and components, the fluid transfers flow and pressure to create linear or rotary motion.

- Hydraulic Cylinders and Actuators: This is where hydraulic energy is converted back into mechanical energy. In a hydraulic cylinder, the pressurised fluid pushes a piston to generate linear movement. For more details and our full range, check out our hydraulic actuators.

- Valves and Control Mechanisms: Valves control the flow and direction of and prevent fluid, ensuring that the right amount of pressure reaches each part of the system. Control valves are crucial in directing fluid flow and regulating pressure.

- Reservoir: The reservoir stores hydraulic fluid when it’s not in use. It also cools and can contain filters that clean the fluid.

- Hydraulic Motor: In some systems, a hydraulic motor converts hydraulic energy into rotational motion, enabling applications like drilling or piling. Hydrastore offers a comprehensive range of hydraulic motors. To learn more, visit our motors page.

How Hydraulics Work: The Role of Pascal’s Law

The operation of hydraulic systems is based on Pascal’s Law, named after Blaise Pascal, a French mathematician. Established in the mid-17th century, for the most part the law still governs how we create the power needed for most industry sectors to operate. It states that pressure applied to a confined fluid is transmitted undiminished in all directions. This principle allows hydraulic systems to multiply force, making it easier to lift heavy loads with less input force.

- Pressure Transmission: When pressure is applied to one part of the fluid, it spreads equally throughout the system. For example, when you push down on a brake pedal, the fluid inside the system moves with equal pressure to the brakes at each wheel.

- Force Multiplication: This uniform distribution of pressure lets hydraulic systems multiply force. So, a small force applied on one end can generate a much larger force on the other, which is why hydraulics are a powerful medium for lifting and moving equipment.

Hydraulic Systems in Action

Hydraulic systems are used across countless industries; in fact, it’s unusual to find an industrial setting without hydraulics. Here are just some of the common uses:

- Construction Equipment: Excavators and bulldozers rely on hydraulic cylinders to lift and move heavy materials.

- Manufacturing Machines: Presses and stamping machines use hydraulics for high-precision tasks, applying consistent force.

- Automotive Brakes: Most modern car braking systems use hydraulics to transfer the force from your foot on the brake pedal to the brake pads.

- Agricultural Machinery: Tractors and combine harvesters use hydraulic systems for steering, lifting, and other essential functions.

How to Maintain a Hydraulic System

Regular maintenance ensures that hydraulic systems work efficiently and last longer. Here are some essential maintenance tips:

- Check Hydraulic Fluid Levels: Low fluid can cause cavitation, overheating and reduce efficiency. Always keep the reservoir filled to the appropriate level.

- Inspect for Leaks: Look for leaks around hoses, fittings, and connections. Fluid leaks can lead to flow and pressure less and affect the system’s performance.

- Replace Filters Regularly: Filters help keep contaminants out of the fluid. Regularly replacing filters extends the life of the hydraulic components.

- Monitor Pressure and Flow: Use gauges to check fluid pressure and flow rate. Inconsistent readings can indicate issues within the pump or control valves.

Proper maintenance ensures your hydraulic system runs smoothly, reducing the risk of breakdowns and costly repairs.

Why Are Hydraulic Systems Used in Modern Industry

Hydraulic systems help industries by turning mechanical energy into an accurate, powerful movement. They are essential on construction sites and in factories. Their dependability and ability to build considerable force from compact systems make them useful for many tasks.

Learning hydraulic principles is vital for using and keeping machines in good shape, whether you work with hydraulic machines or are just curious about how these systems work. With proper knowledge and frequent upkeep, hydraulic systems will probably continue pushing, lifting, and driving our world for many years to come.

Posted by admin in category Hydraulic Systems Advice on Friday, 25th April 2025